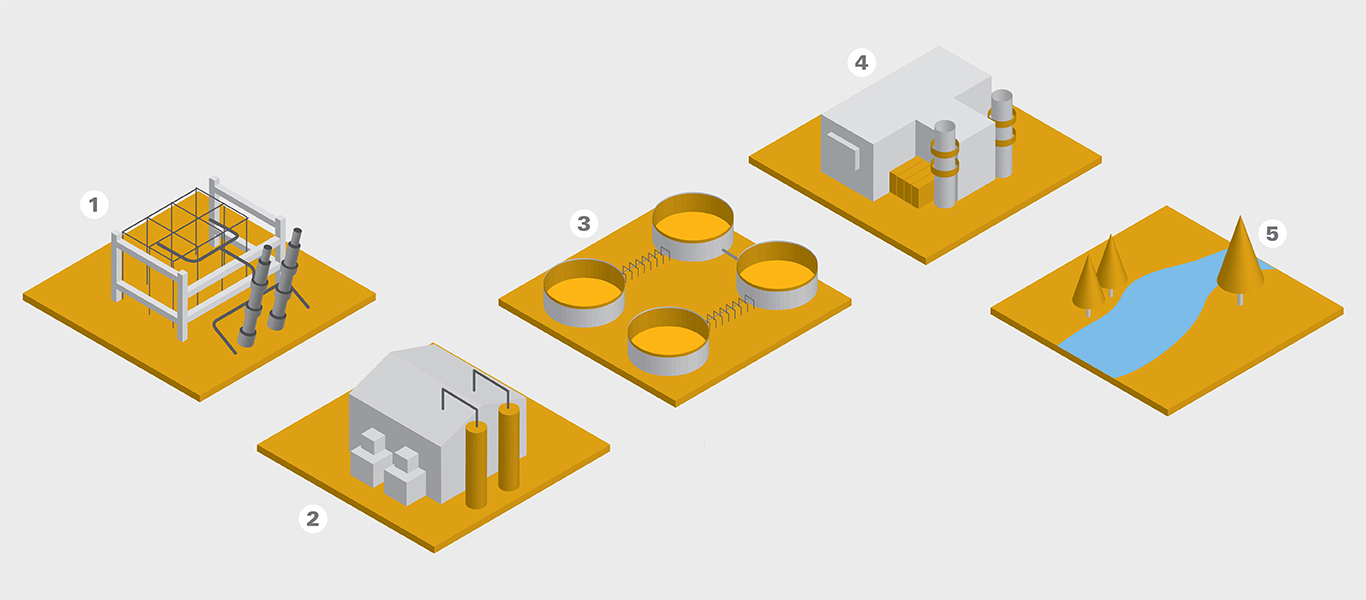

How Long Lake works

1. Turning oil sands into crude oil starts at the SAGD well pads

Horizontal wells are drilled in pairs to access the oil sands deposits that are located more than 200 metres underground. One well injects steam into the oil sands deposit. The heat from the steam melts the bitumen, enabling it to flow along with water that forms as the steam cools, to the lower well. The bitumen and water are then pumped to the surface.

2. The next step: Production separation and treating

Bitumen and water are separated into two streams: water (which is cleaned and reused to generate more steam) and bitumen (which is mixed with diluent, a light hydrocarbon that dilutes the very thick bitumen and enables the separation process).

3. Transport to market

A pipeline connects Long Lake to the Cheecham Terminal, located about 20 kilometres south, where it links into the Athabasca Pipeline system. Crude oil from Long Lake is processed in refineries throughout North America to generate a range of consumer and industrial products including gasoline, diesel fuel, jet fuel and petroleum-based products such as plastics, beauty products, paint and carpet.

4. Supporting the entire facility is the cogeneration unit

Long Lake features a cogeneration unit that provides steam for the SAGD operations and electrical power for the site. CNOOC generates more electricity than the site requires, selling this excess to the Alberta power grid.

5. The final step in the process: Reclaim the land

All oil sands producers are required to restore the landscape to its equivalent capacity. At Long Lake, portions of our lease are already undergoing reclamation, even though the facility will be in operation for decades to come. Reclamation efforts to date include the planting of more than 660,000 trees and shrubs to mitigate areas disturbed by seismic and core hole exploration.

Learn more about our culture of safety and sustainability

Our commitment to sustainability

Safety Committee ensures a Safety First mindset

Caribou habitat restoration